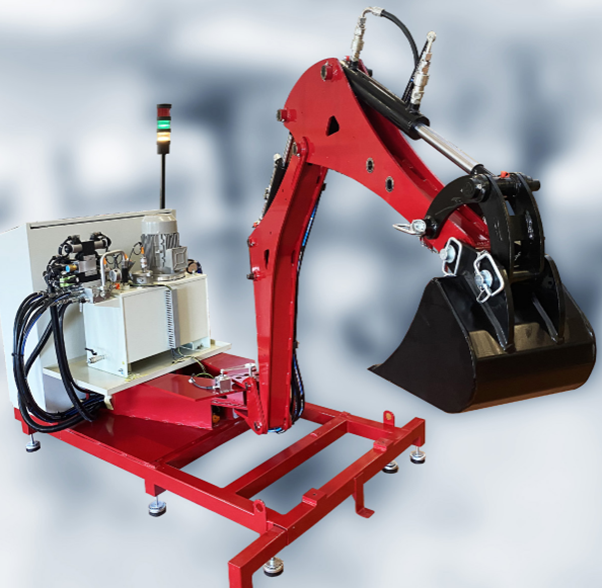

ECOLBRAS: CONSTRUCTION EXCAVATOR ARM

This system needs to be installed into a safety zone (dimensions 3900 mm x 5200 mm x H 2200 mm).

The technologies used include on/off hydraulic, proportional flow and proportional pressure, electrical, and communication network Ethernet Modbus, Ethernet IP, and IO Link.

A touchscreen graphic display and analog joysticks control the hydraulic arm,

thus providing a comprehensive didactic approach to both the world of hydraulics and Industry 4.0.

The EcolBras can be used as a hydraulic bench. A touchscreen console allows the EcolBras to function as a real robot. Object grasping, movement along three axes, and object placement.

HYDRAULICC 1 - Load tilting device

**"HYDRAULICC solution consists of 3 workstations focused on operative parts.

Each workstation includes:

- An operative part (PO) with a pre-actuator plate support,

- A hydraulic Power Pack,

- A control command cabinet,

- A set of pre-actuator plates with either an ON/OFF or Proportional solution,

- A stand for flexible hoses and electrical safety cables.

A proportional valve is used to control the position of the load

An incremental encoder provides the position feedback

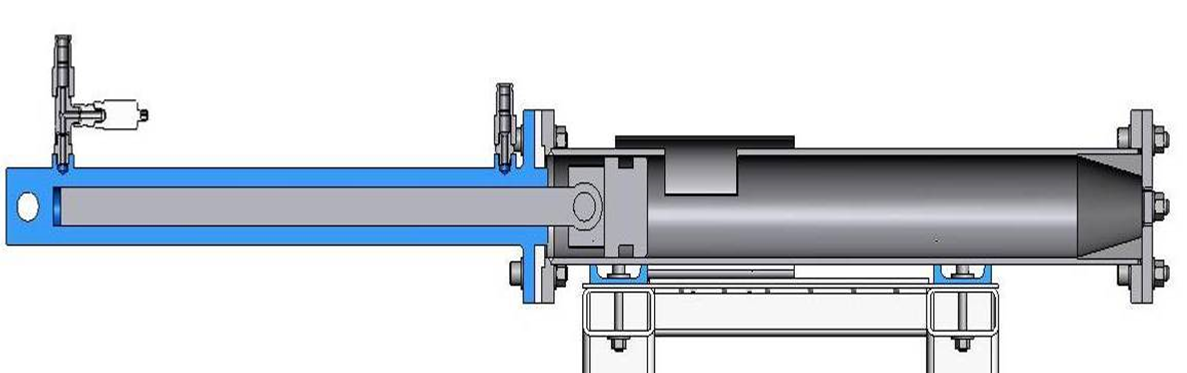

HYDRAULICC 2 - Extrusion press

The extrusion press simulates the process of manufacturing aluminum profiles. It is the most economical process for transforming aluminum. The process used is extrusion.

A proportional pressure limiter is used to control the pressure during extrusion.

An analog pressure sensor allows pressure measurement

HYDRAULICC 3 - Screw feeder

A proportional flow regulator is used to control the production speed

An incremental encoder provides the speed feedback

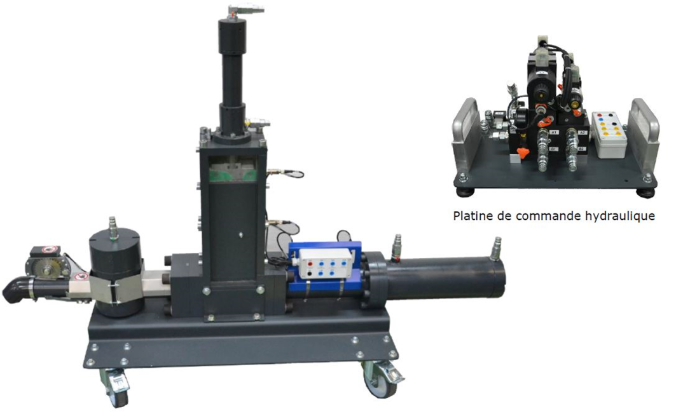

Hydraulic press compactor

It includes electromechanical and hydraulic functions contributing to the compaction of shredded materials and thus to the manufacture of briquettes

It is designed as an autonomous operational unit that can be connected to our own distribution and control solutions, as well as to any type of simulator or hydraulic test bench available in the workshop

Paper waste compactor

This new version implements and makes accessible the new concepts of Industry 4.0 in a very comprehensive and advanced way, both in terms of hardware and digital aspects. It offers a variety of technologies, including Pneumatic, Pneumo-Hydraulic, and Hydraulic systems.

Pneumo-hydraulic technology combines compressed air (pneumatic) and pressurized oil (hydraulic) to generate high forces with precise motion control.

RECYCLICC - Complete production plant

Recycling line and briquette manufacturing for Paper/Cardboard/Wood by hydraulic compaction.