Troubleshooting in VR

Diagnoz VR

Learn and improve troubleshooting skills through a Virtual Reality simulator.

METAQUEST3/3S

Diagnoz VR requires only a Meta Quest 3/3S and 2 headset - purchased separately (Meta Quest 3 or 3S is recommended).

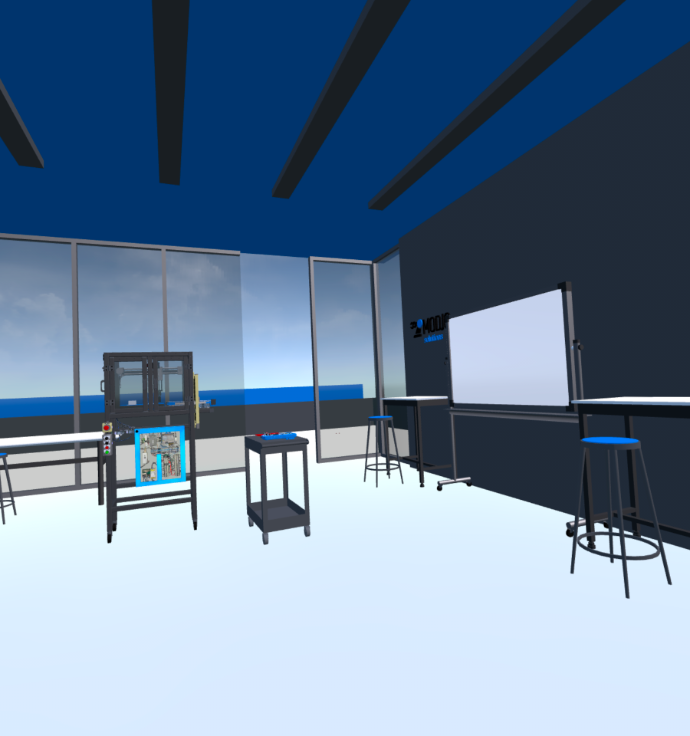

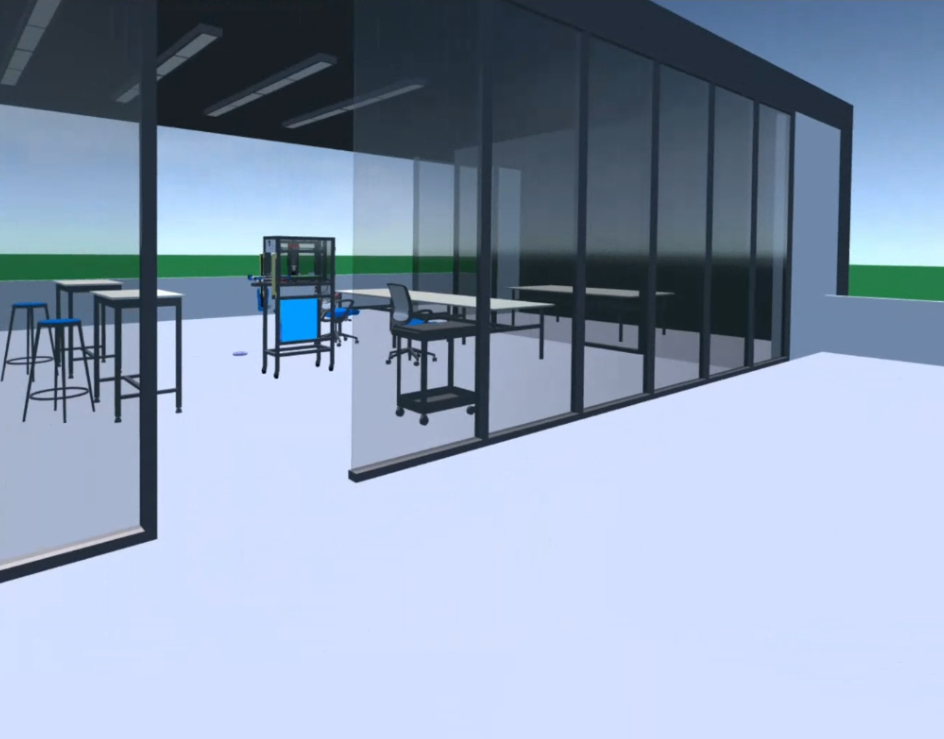

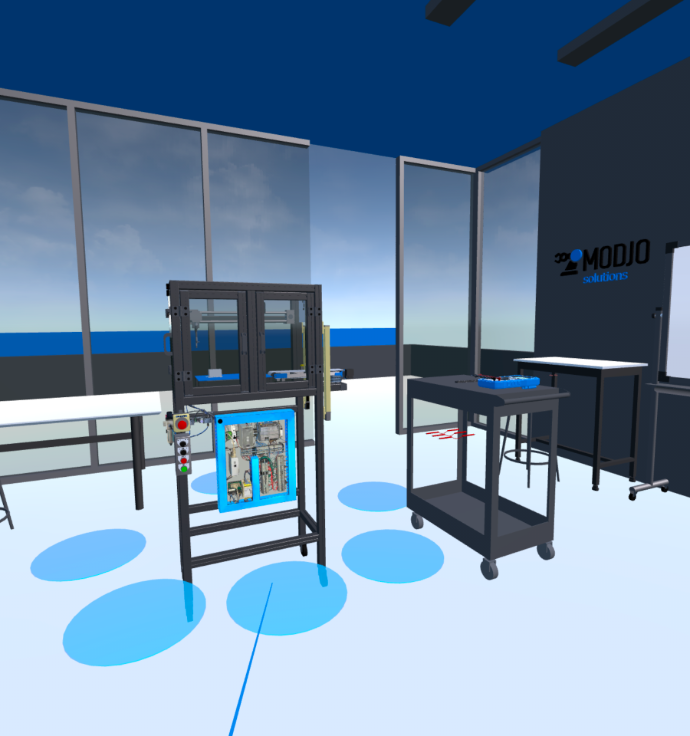

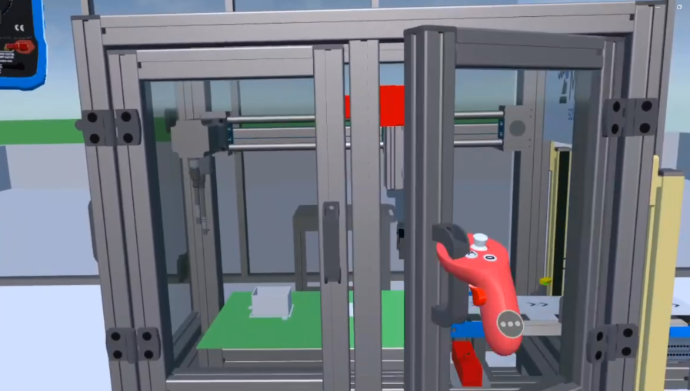

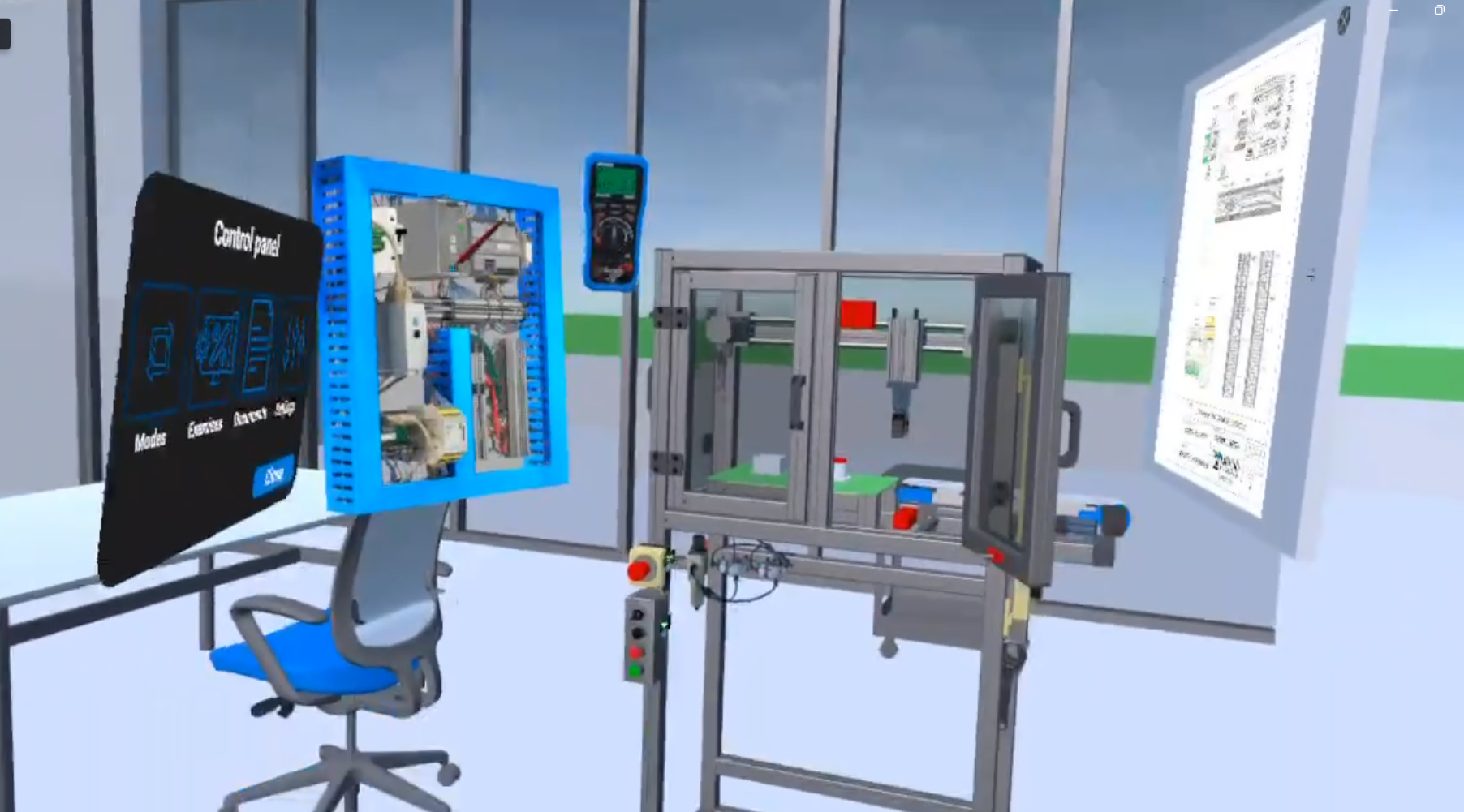

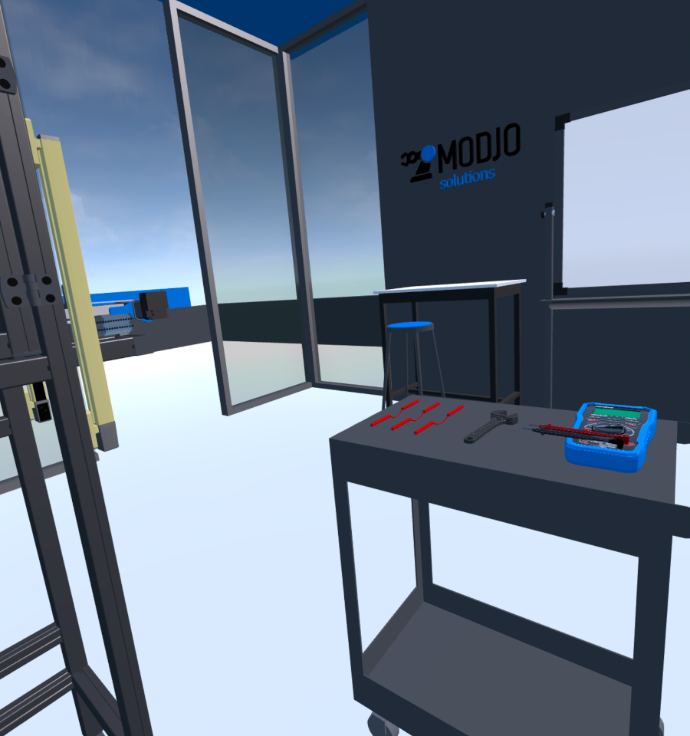

THE ENVIRONMENT

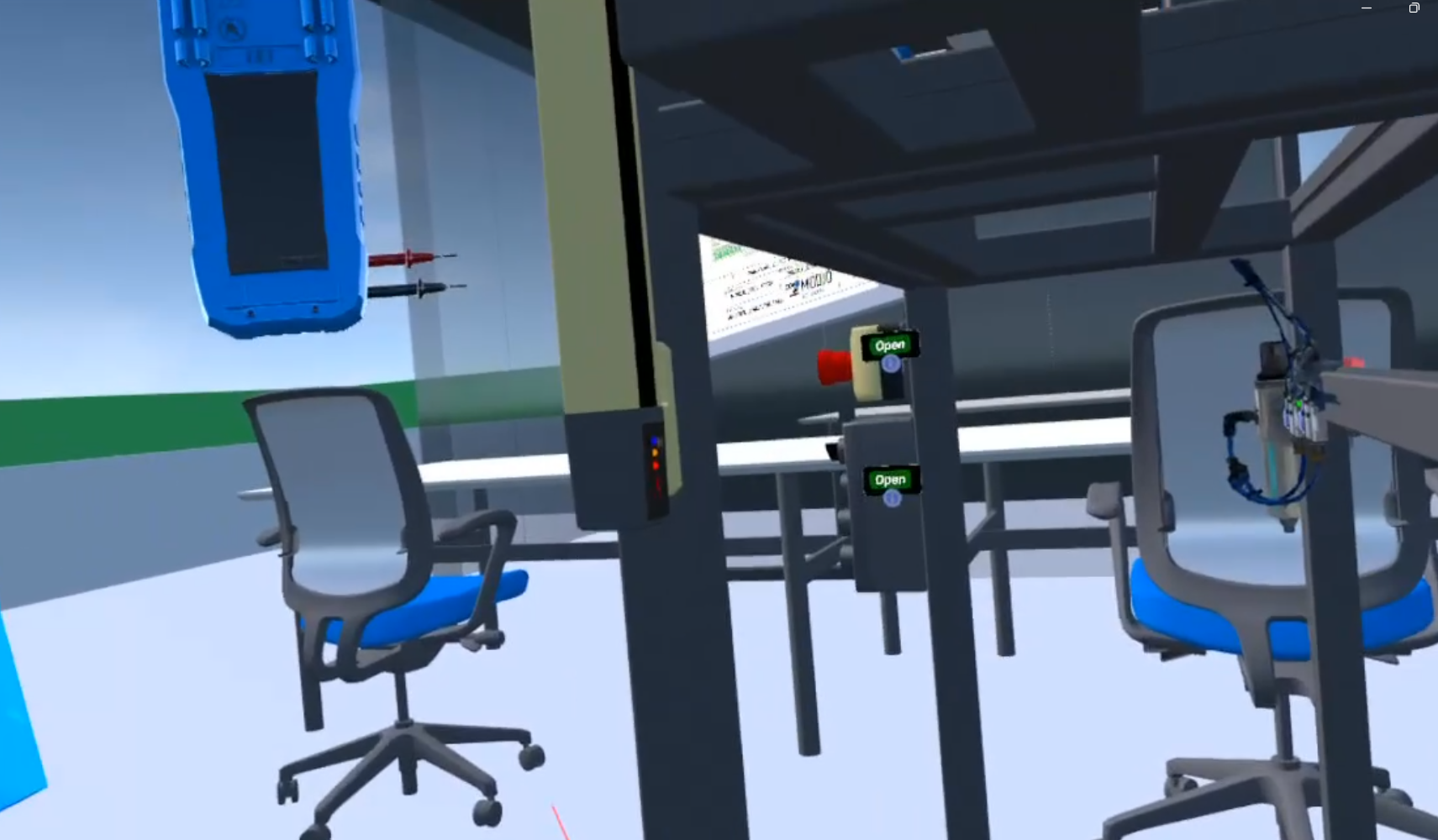

Students will explore the stand-alone machine in its natural environment, with three rooms to discover, including a classroom lab where the machine is located.

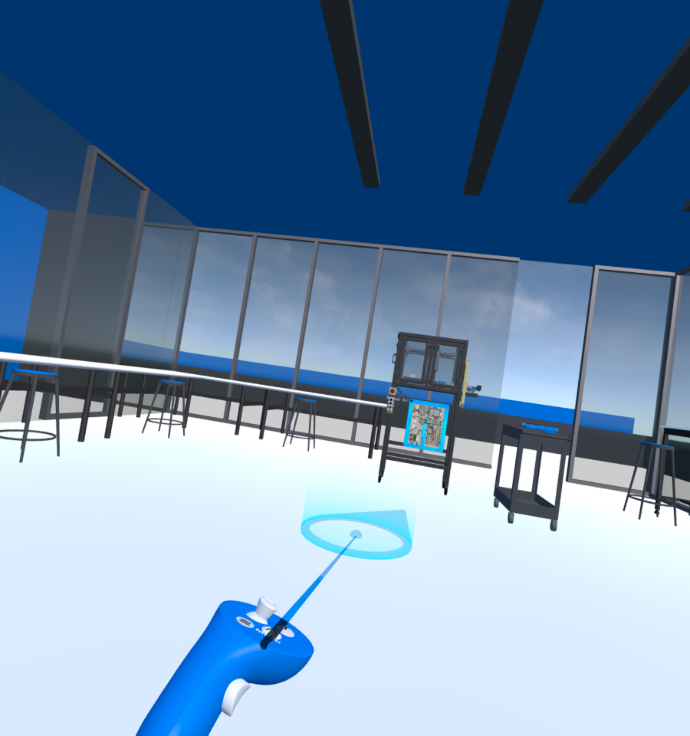

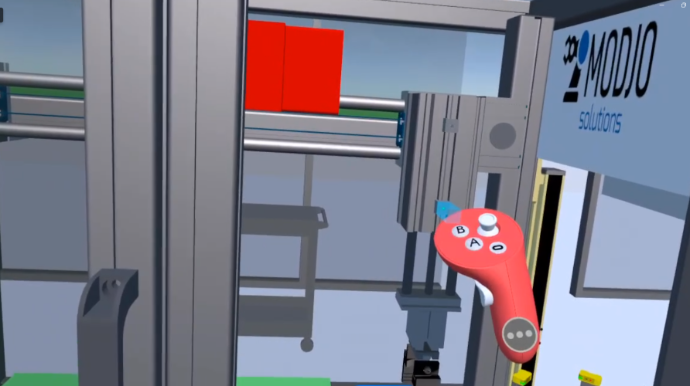

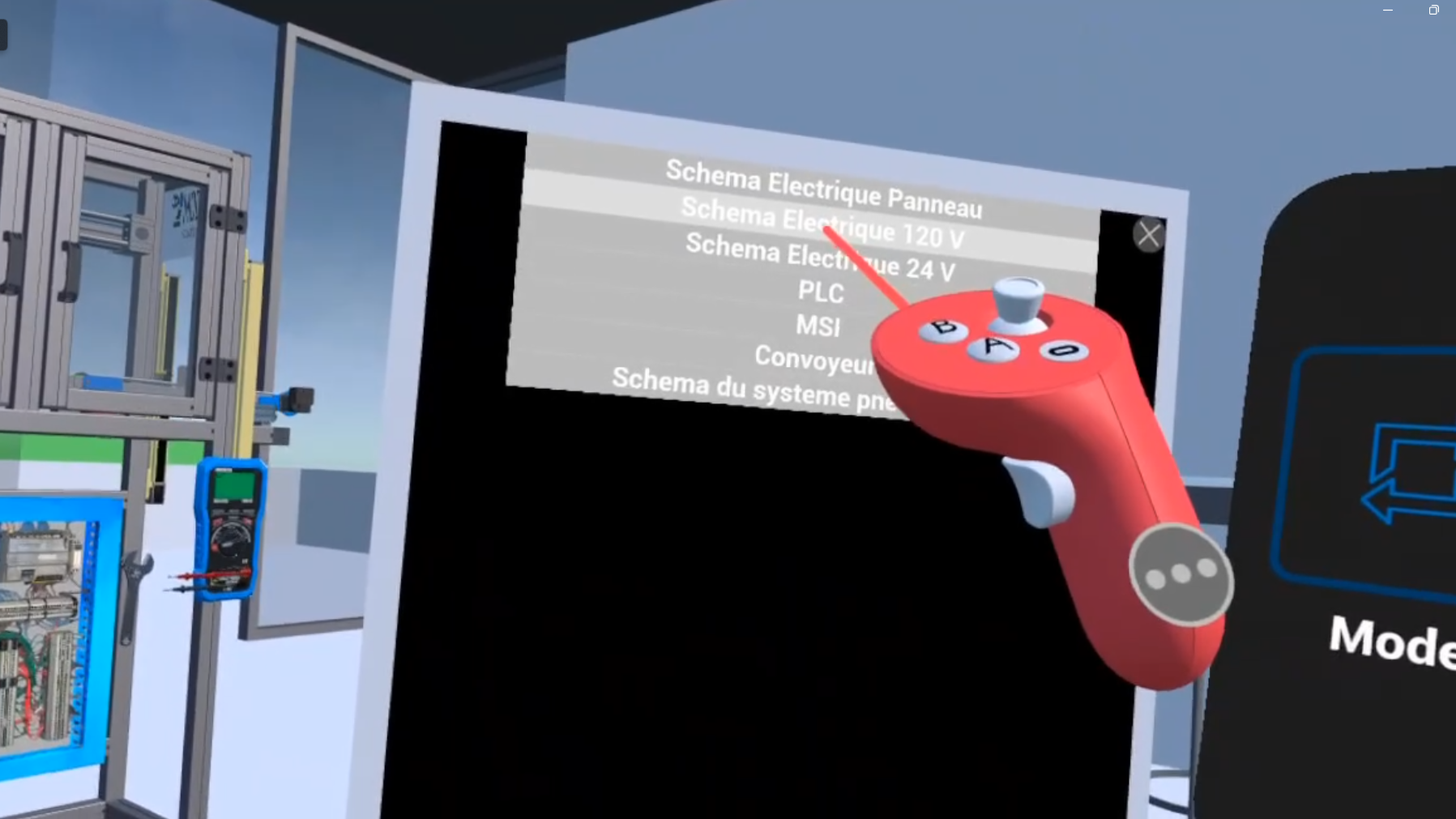

EASY NAVIGATION OPTIONS

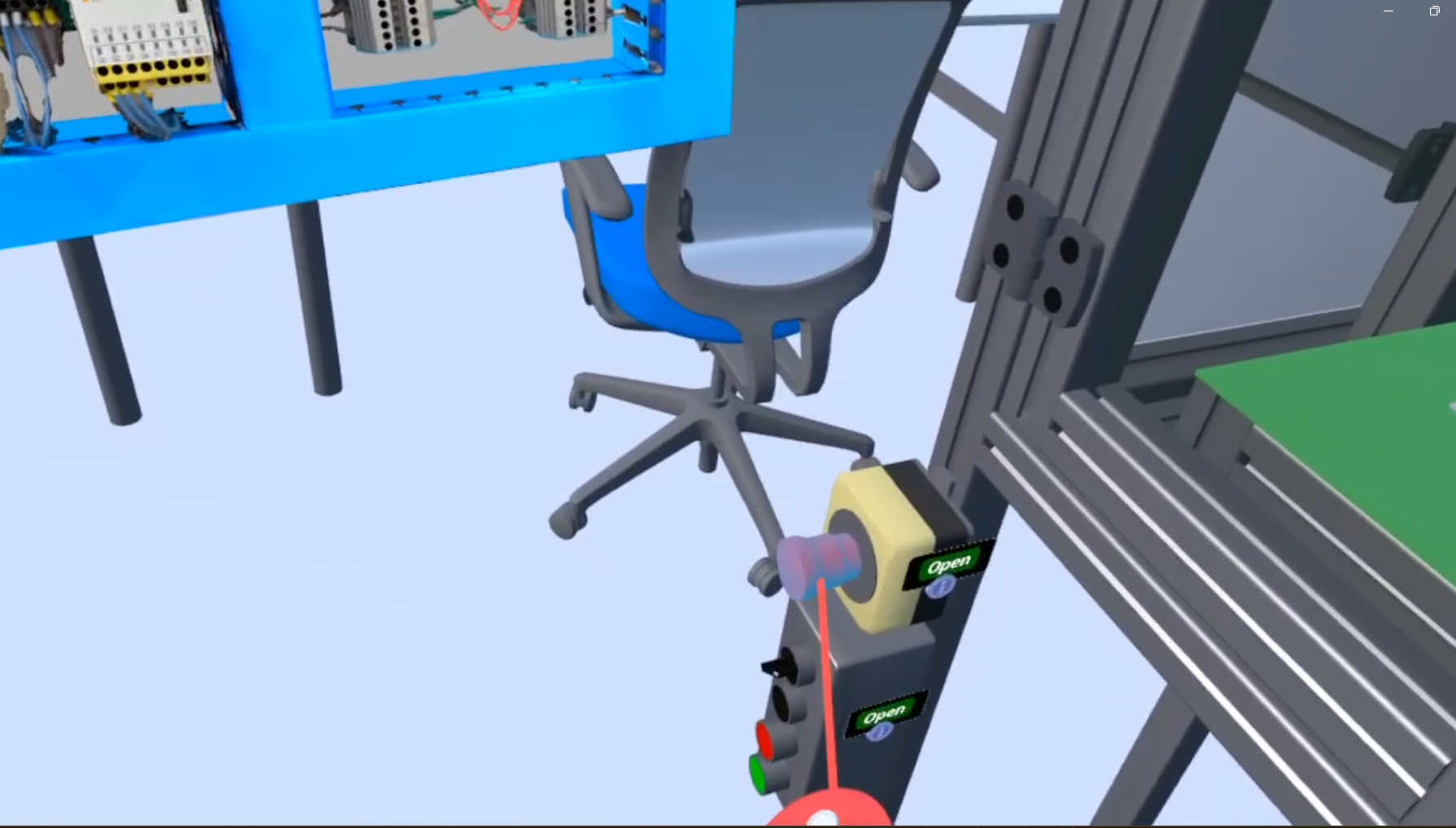

Simply use the point-and-release control with the joystick to move from one location to another.

Use the menu to select the "fixed position" option if you prefer to remain near the machine.

Each time you start an exercise, DiagnozVR will automatically position you in front of the machine, so you don’t have to do it manually.

If you prefer students to remain seated during fault-finding labs, we’ve got you covered. This approach helps prevent collisions between students in confined spaces.

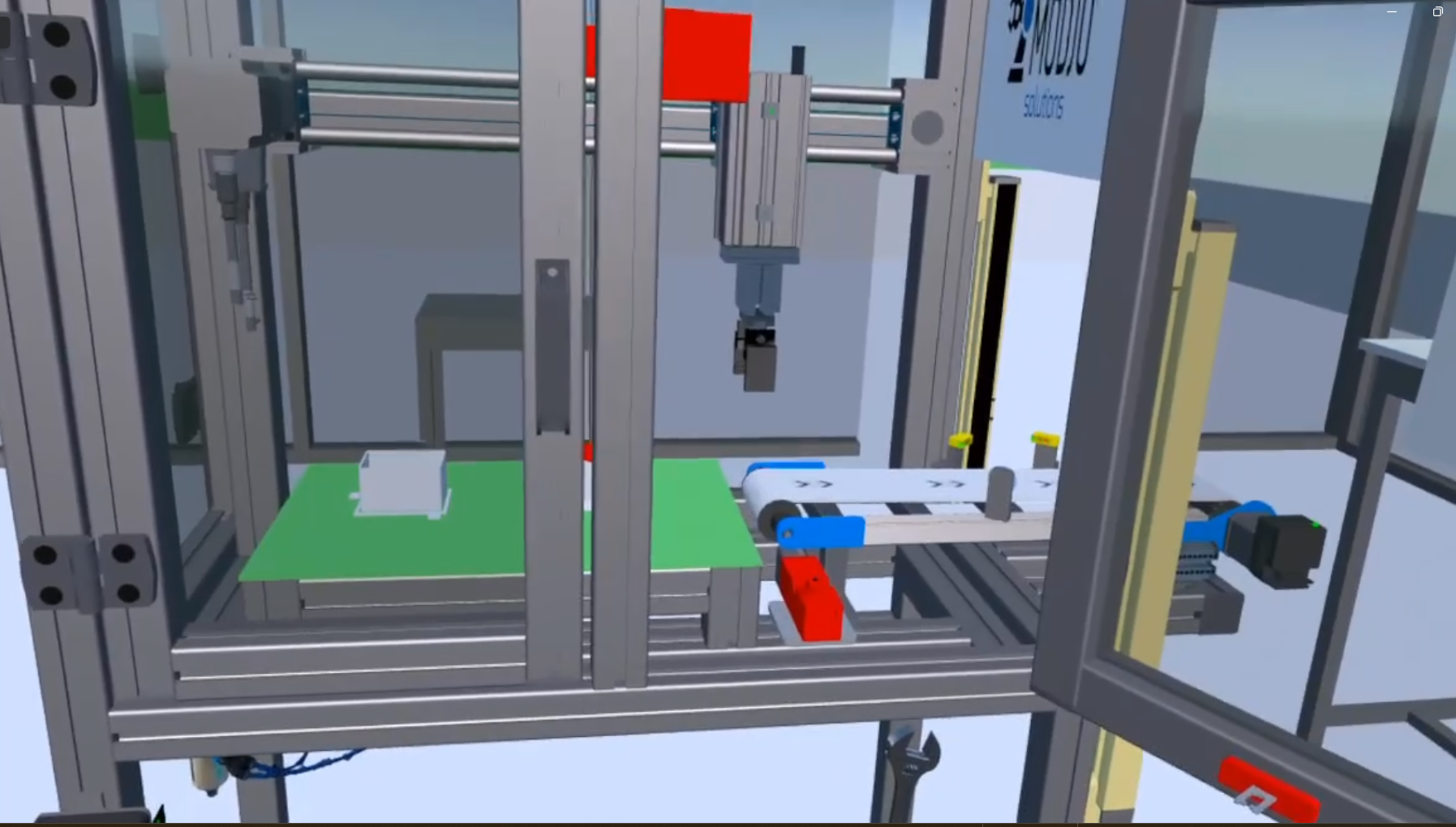

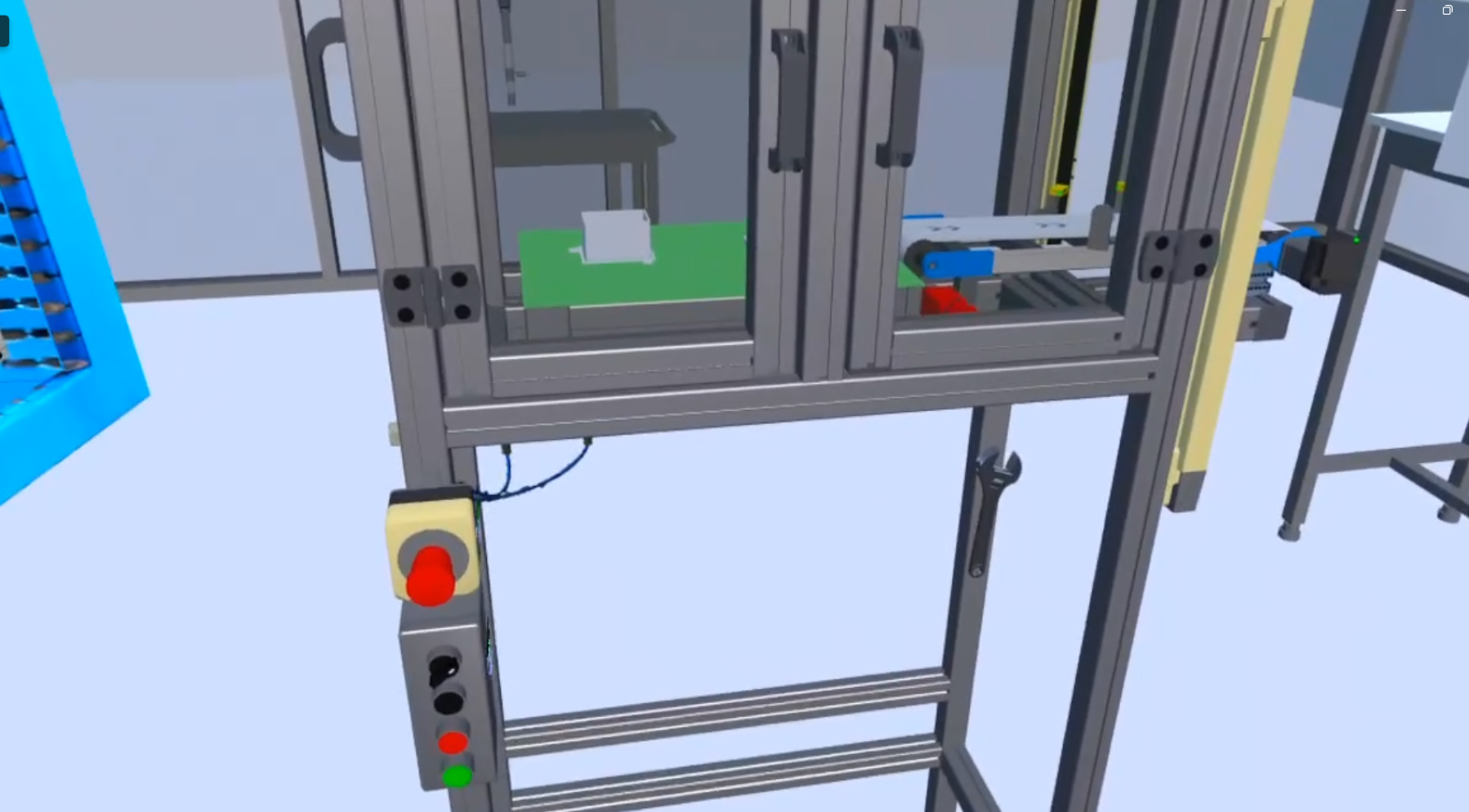

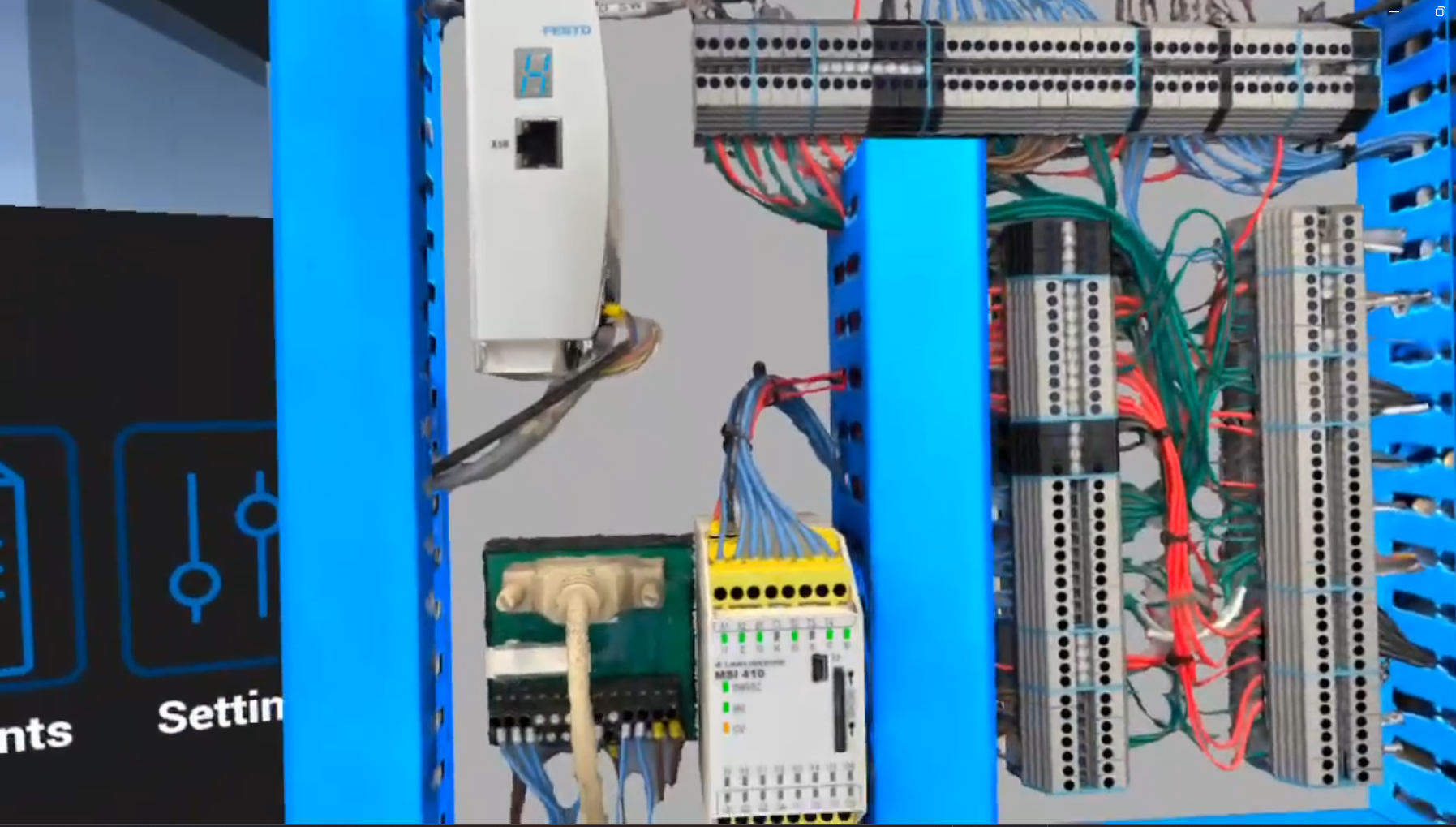

A COMPLETE MACHINE

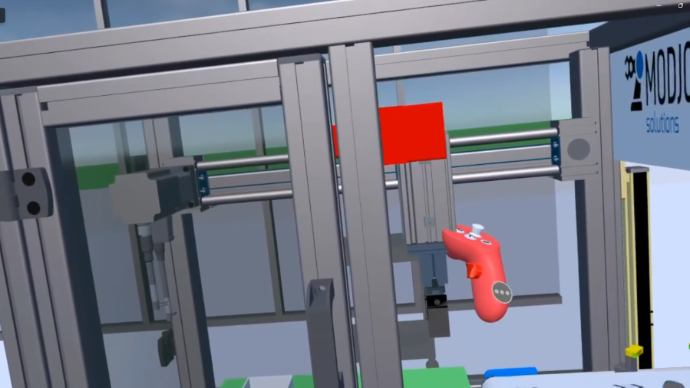

DiagnozVR offers a fully functional pick-and-place 2 axis linear robot equipped with safety components, sensors, a conveyor, a control panel, and controllers (motion, safety, and PLC). This replicates a real machine we have developed for education.

From symptom recognition to fault diagnosis and repair, we provide a comprehensive 360° application that covers a wide range of fault scenarios future technicians, electricians and engineers are likely to encounter in their careers.

EXTENSIVE INTERACTIONS

Open doors, adjust sensor positions, evaluate the status of the light curtain, manually operate pneumatic valves, press buttons, use a multimeter, and add electrical diagrams. DiagnozVR offers a wide range of interactive possibilities.

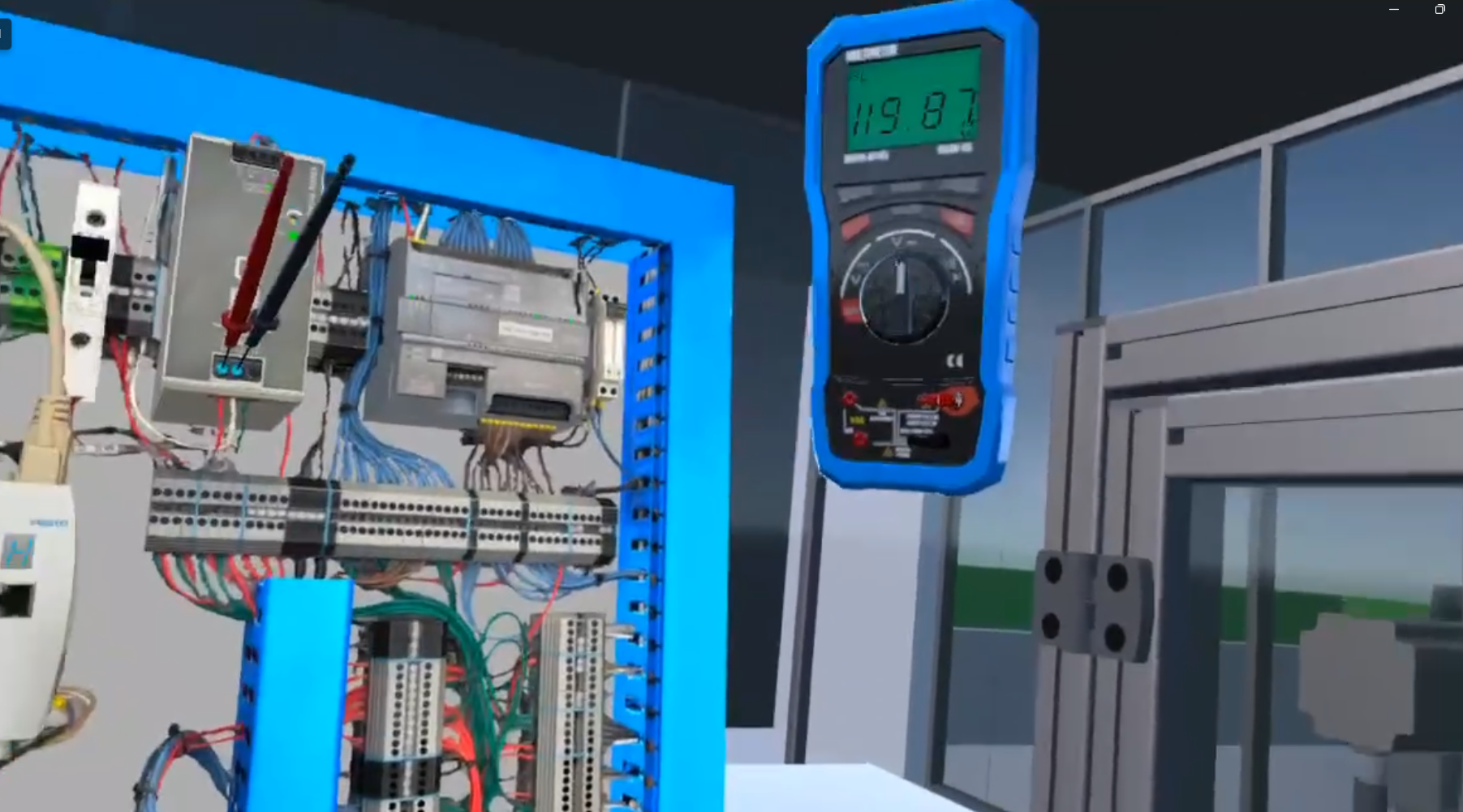

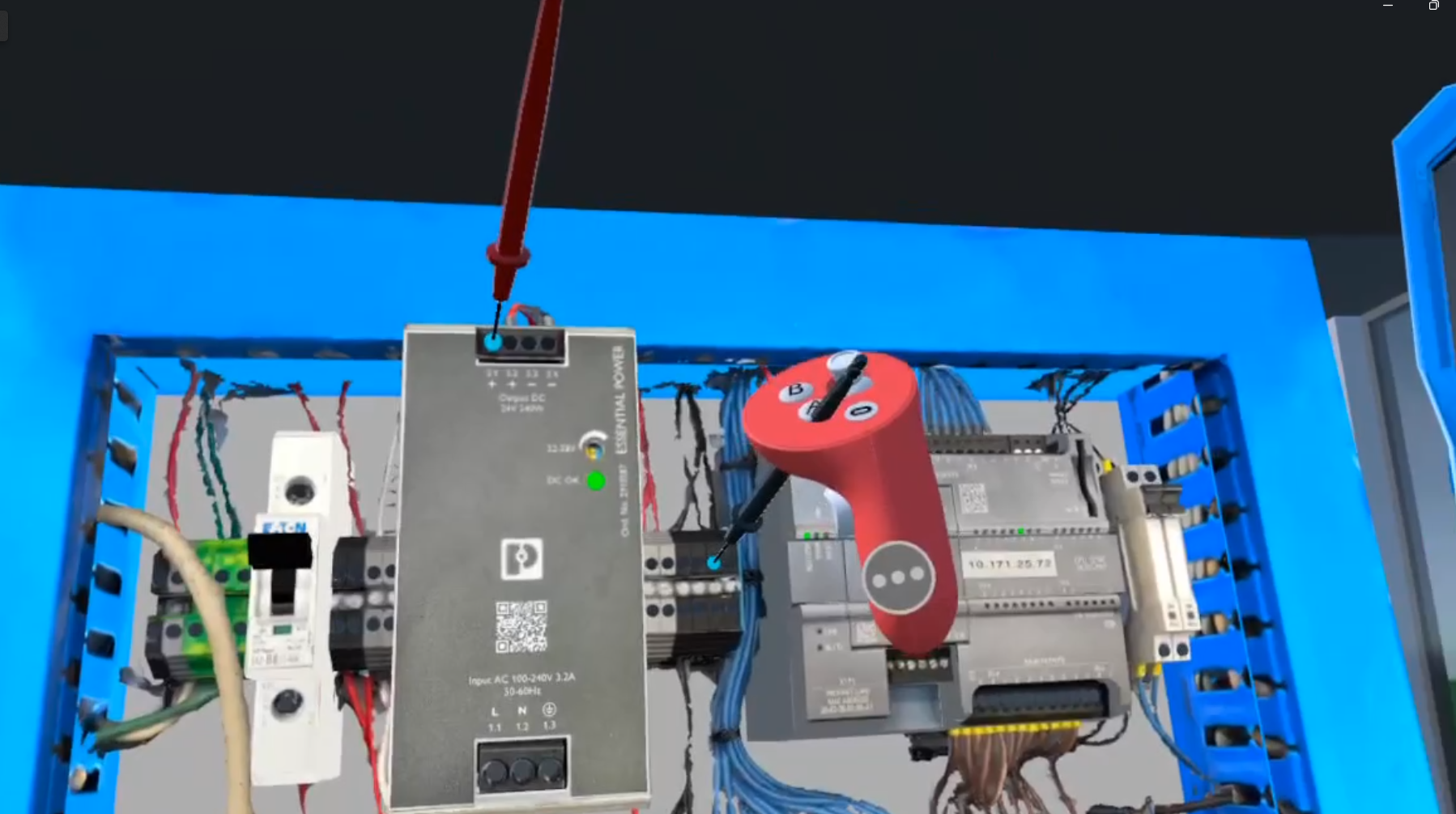

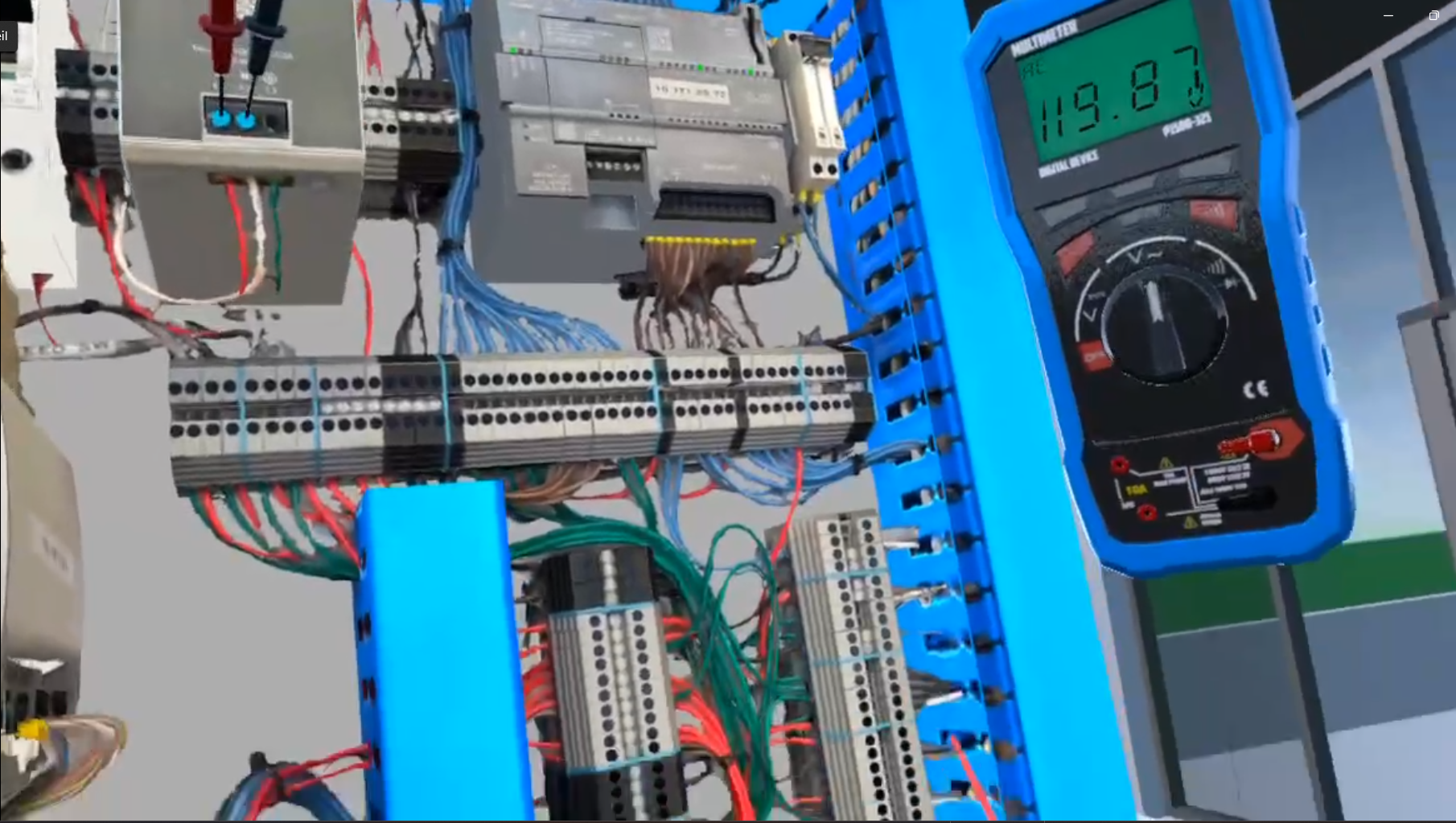

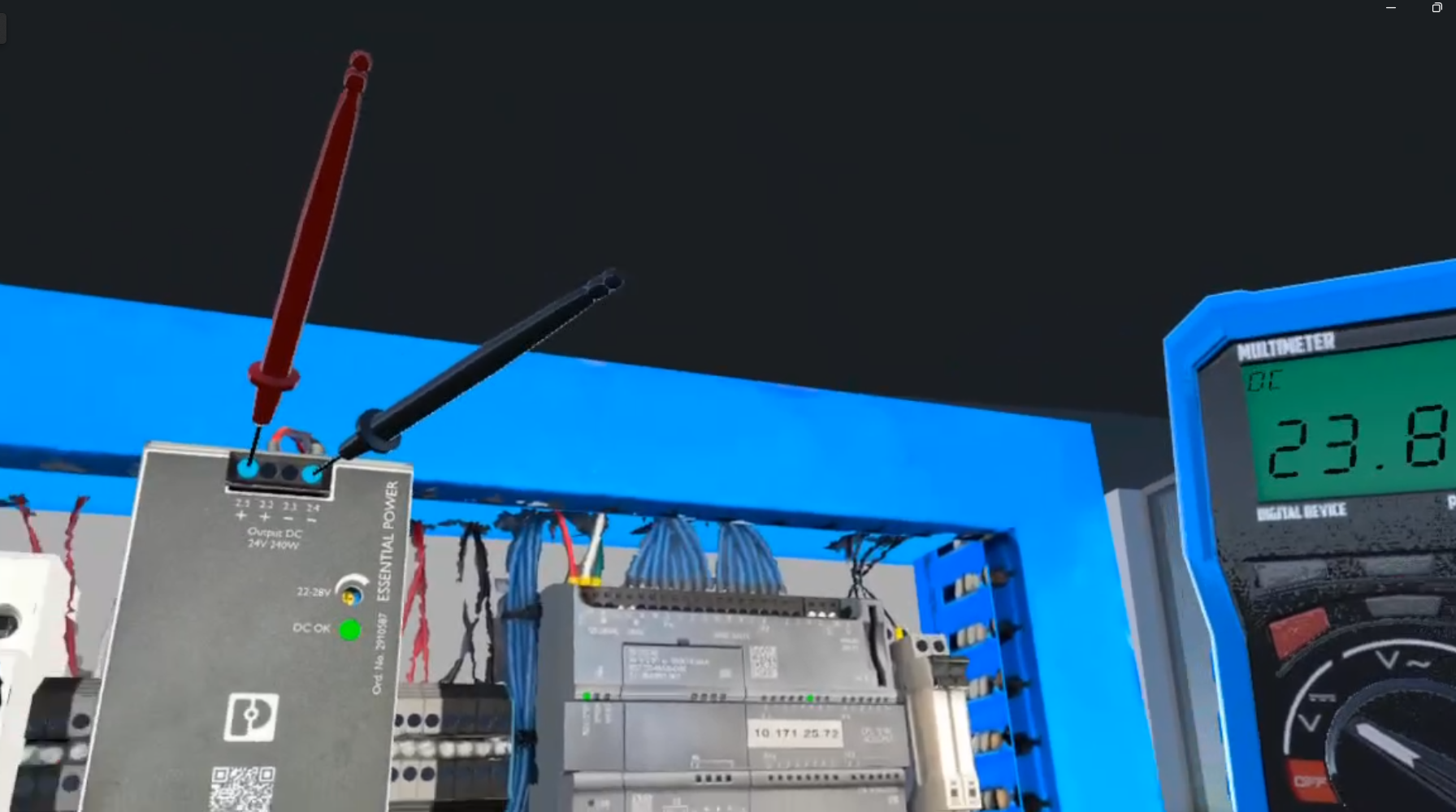

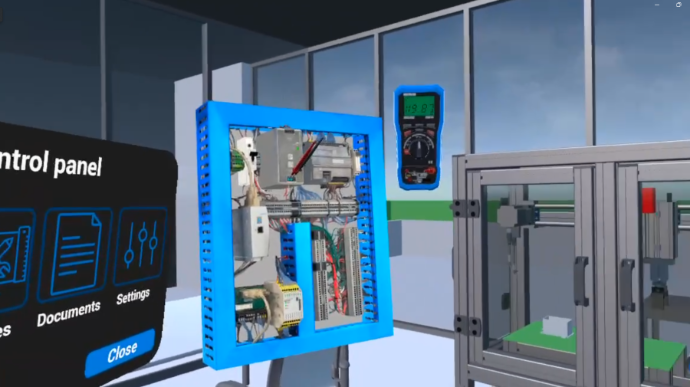

INTERACTIVE MULTIMETER

Use the interactive multimeter to identify electrical faults on the machine. Test continuity, coil integrity, 24V DC, and AC supply voltage. Utilize the probes to measure voltage at the control panel terminal blocks. Open operator panels or inspect safety sensors to pinpoint the origin of the fault.

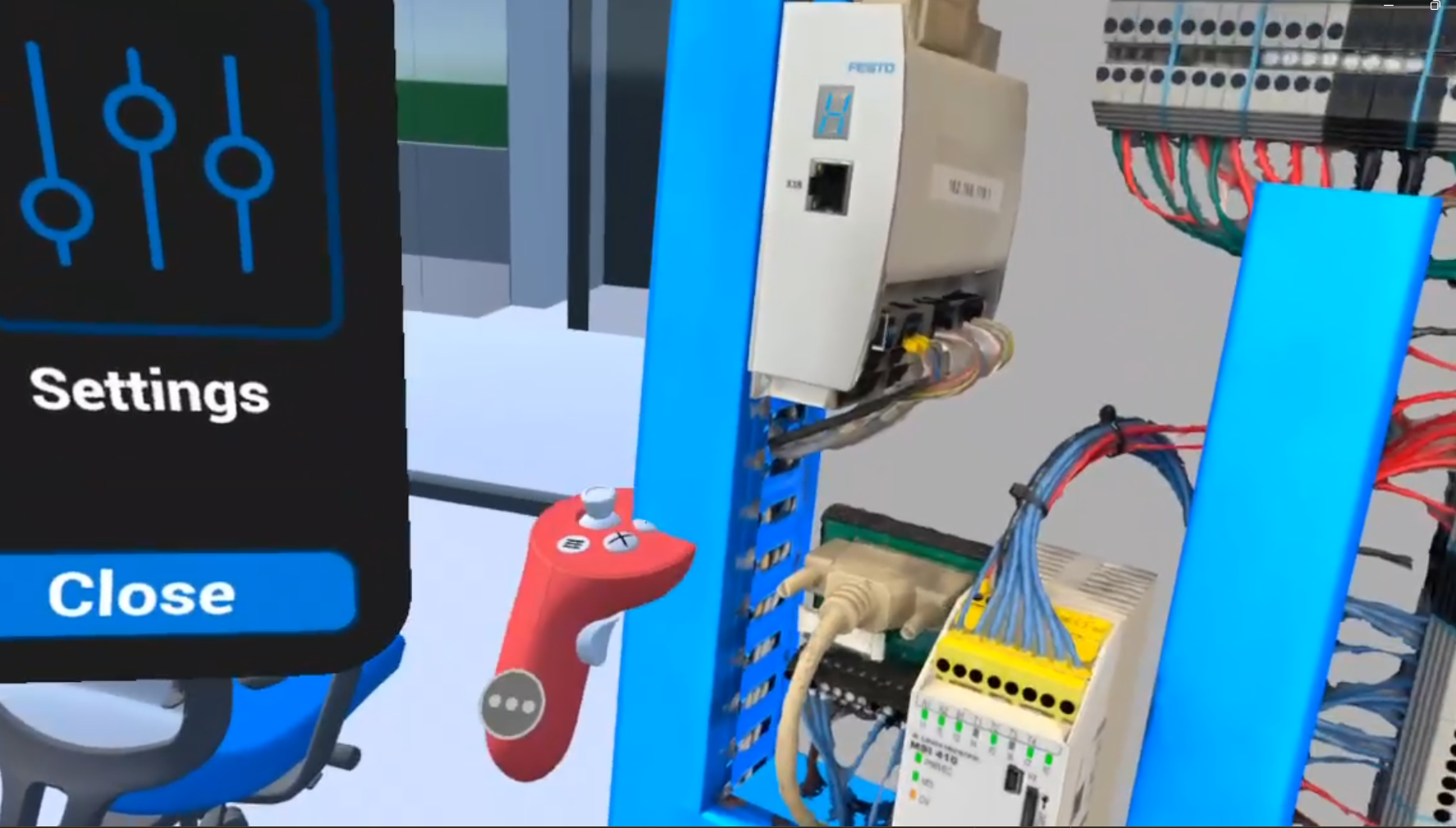

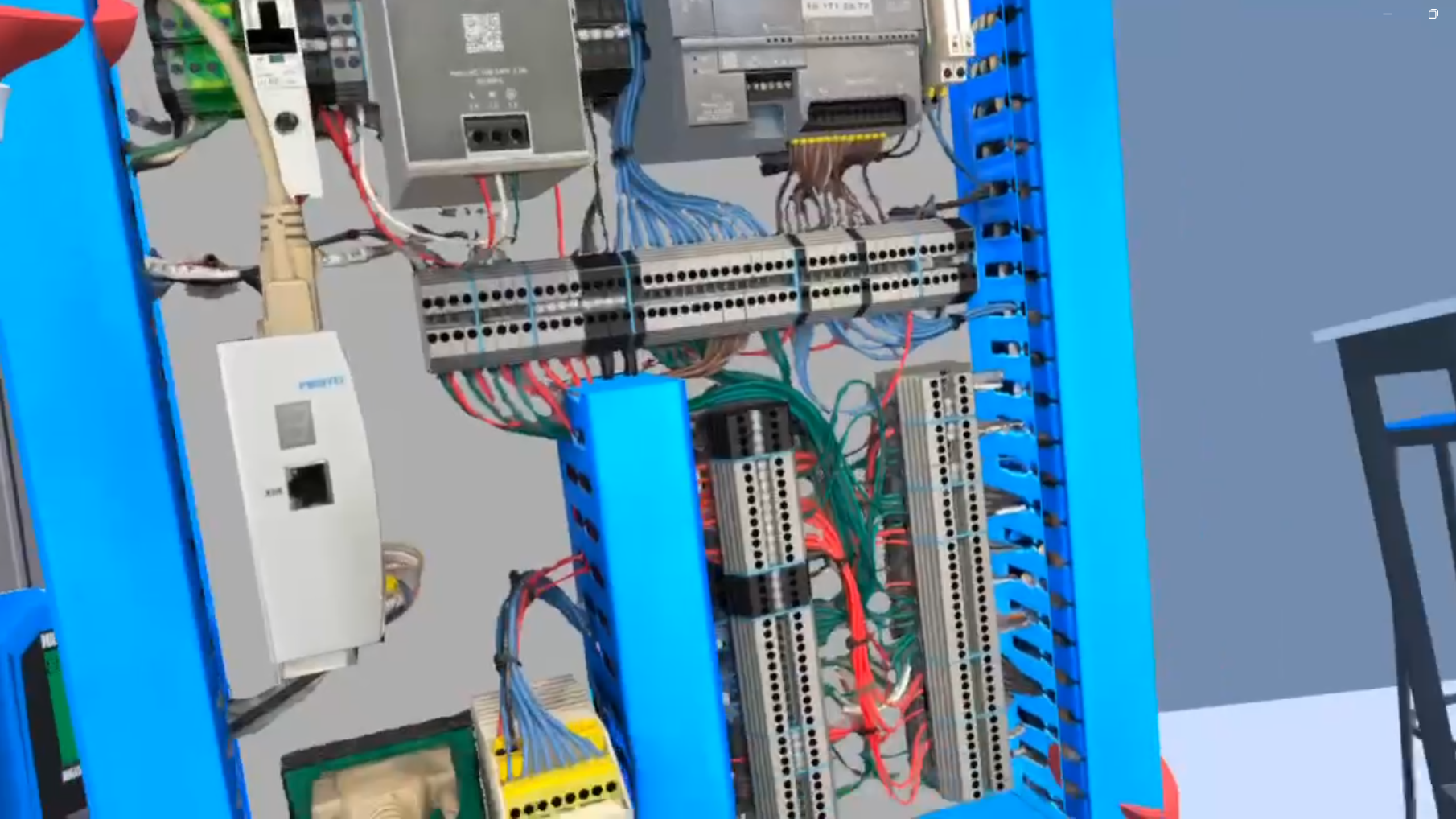

EXTENDED CONTROL PANEL FEATURES

Students will have full access to the control panel. They can move it from beneath the machine and position it strategically to receive feedback from the machine.

Every terminal block on the panel is accessible, allowing students to measure I/O signals on controllers, relays, disconnects, power supplies, conveyors, sensors, and control boxes.

They can zoom in or reposition the panel for a better view. Detailed features display the wiring, I/O allocations, and status directly on the controllers.

ENHANCED ACCURACY

Pointing the multimeter probe at a screw terminal not only provides visual feedback but also triggers a haptic vibration on the controller to confirm proper probe contact. We put a great deal of effort into making the experience feel as close as possible to a real control panel troubleshooting.

VERY INTUITIVE TO OPERATE

Less than 50% of teenagers in North America own a VR Headset. Based on our experience, less than 50% of teenagers have been exposed to a VR environment in the past, with even lower numbers for teachers.

We’ve taken this into account in how we designed Diagnoz VR. There’s no need to be a VR expert to operate the app. Our introductory tutorial helps users learn how to navigate, grab, and interact with objects before starting.

Every active component glows when pointed at, providing clear visual feedback to let users know they can interact with it.

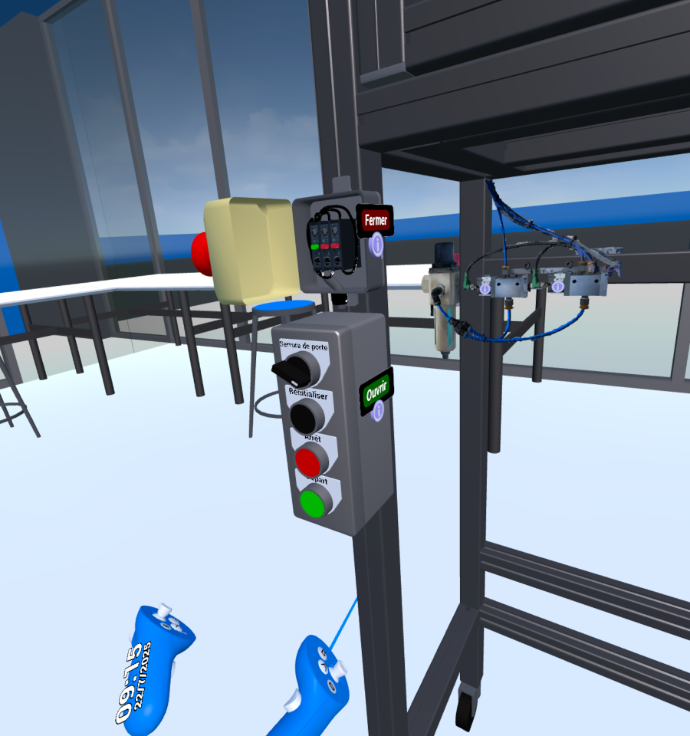

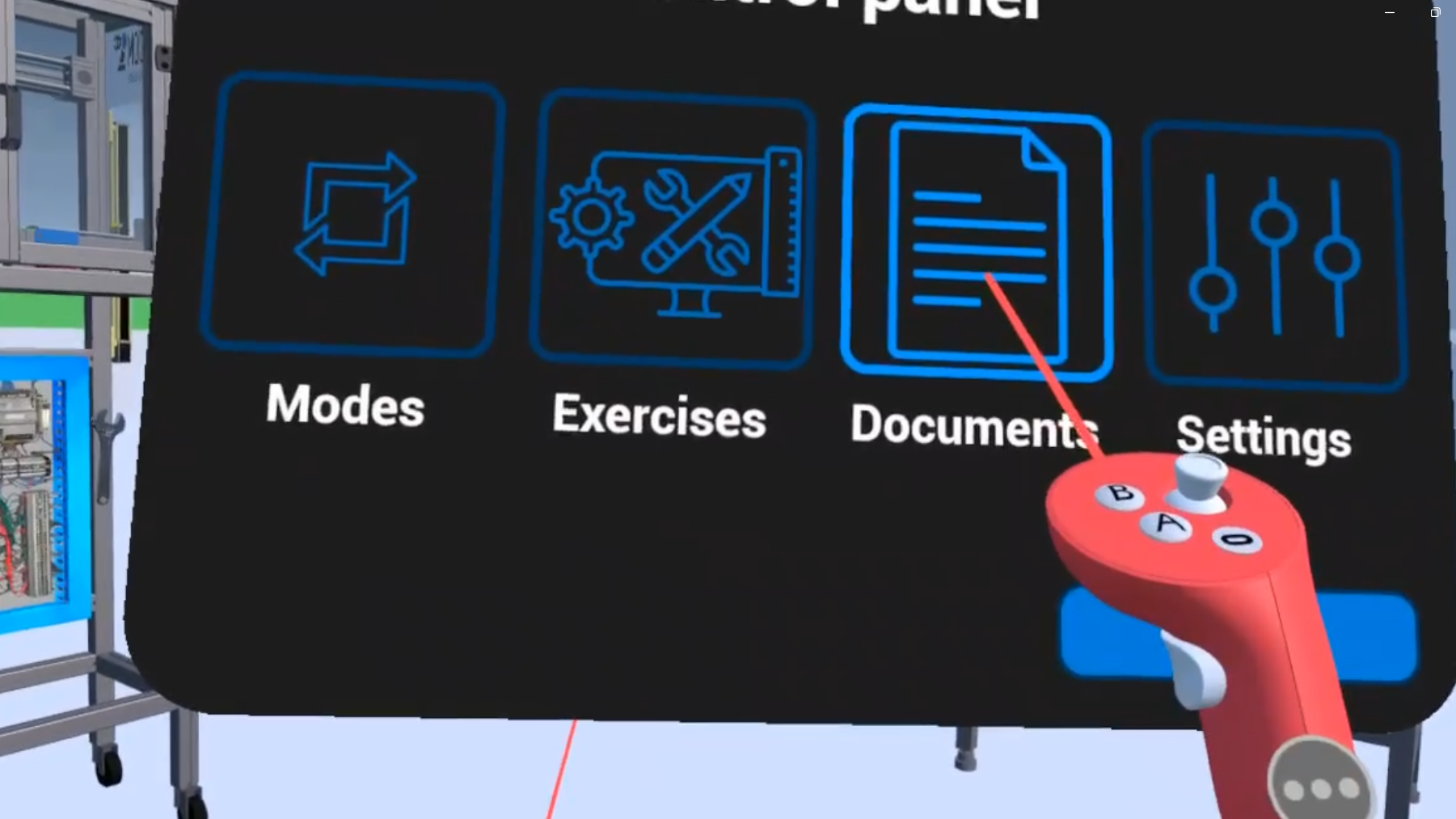

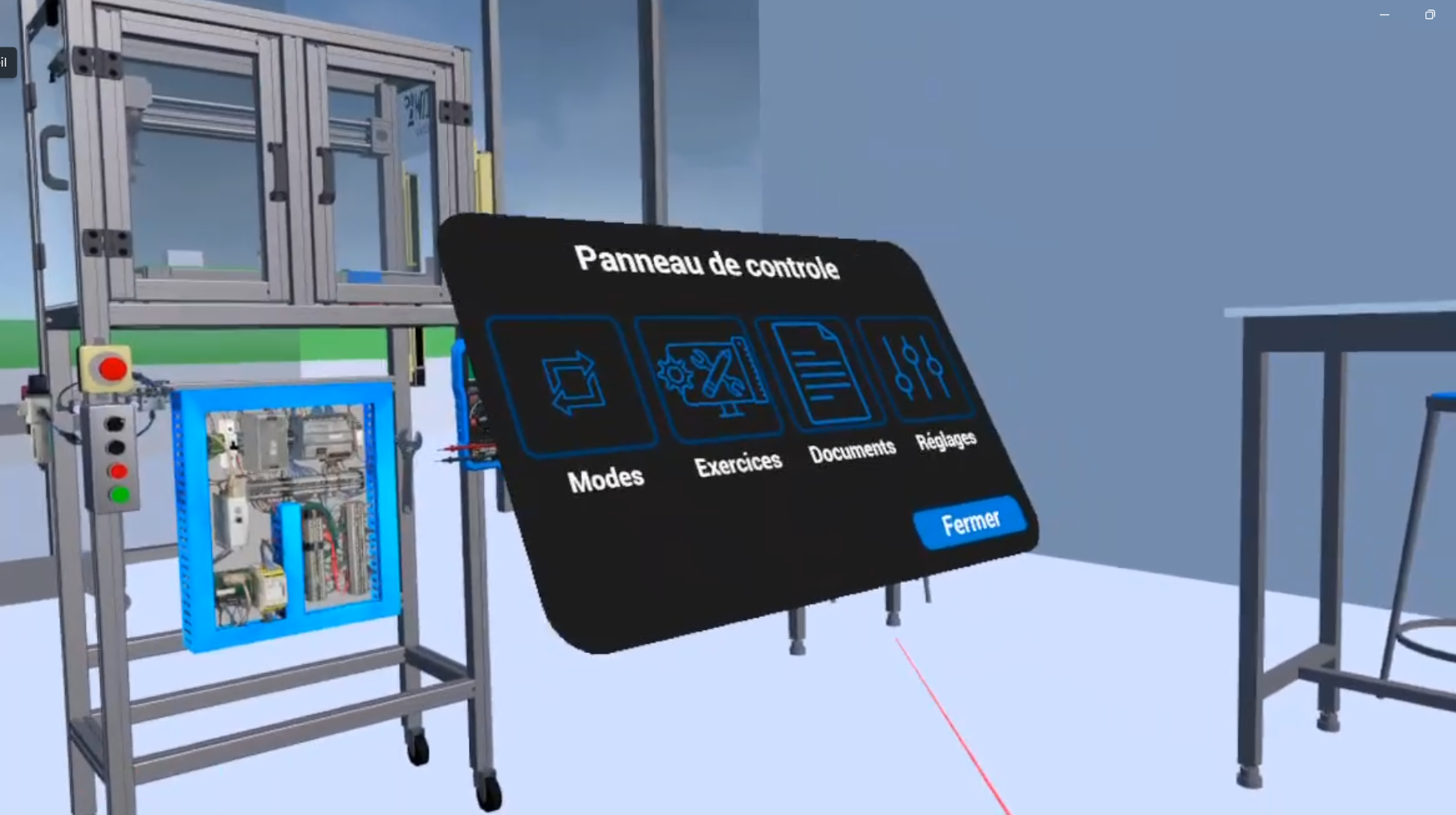

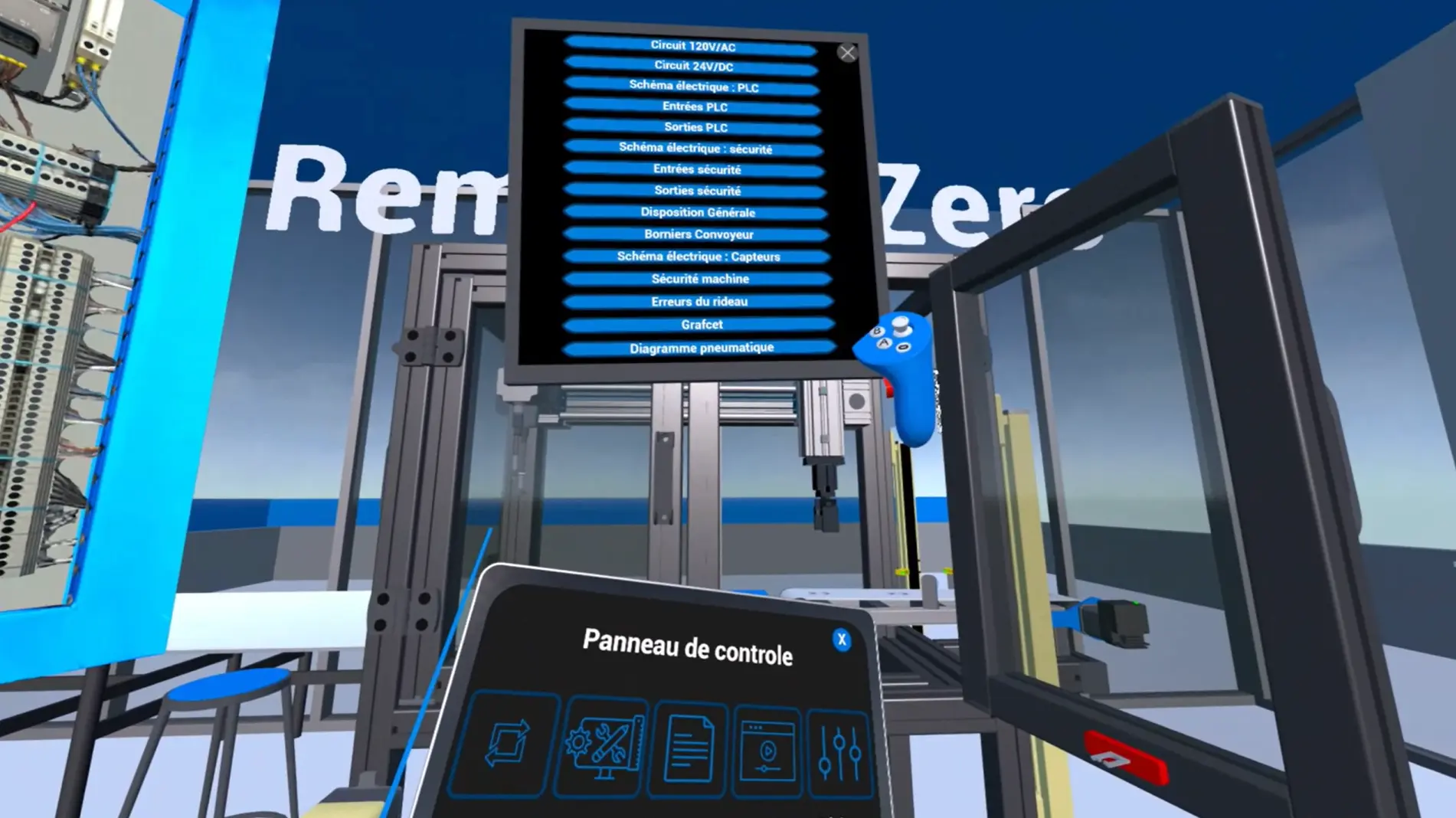

INTUITIVE MENUS

The control panel is highly intuitive and offers various options, including operation modes, exercise selection (based on difficulty level), access to electrical and pneumatic diagrams, and system settings. It can also be strategically positioned within the workspace. Upon selecting an exercise, students are warped in front of the machine, ready to begin troubleshooting.

MULTILINGUAL

DiagnozVR offers its application in both English and French, ensuring accessibility for a wider audience. Stay tuned, as we are actively working on expanding our language options and plan to include many more in future updates. Our goal is to make DiagnozVR a truly multilingual experience, catering to users around the globe.

DEPLOYMENT

We understand that IT setups can vary widely from one school to another. That’s why we provide a simple way to deploy DiagnozVR on your headsets using the SideQuest app. Just install SideQuest on your MetaQuest and search for the app in the store.

If you prefer a more formal and professional approach to managing your headset fleet and applications, DiagnozVR can also be deployed through ArborXR for a monthly fee. Educational packages are available.

TROUBLESHOOTING

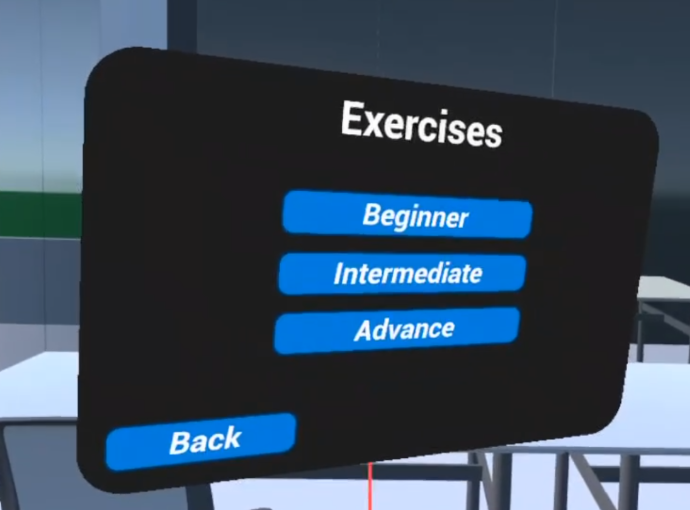

MODE

Start by selecting the difficulty level you want students to experience. Beginner exercises focus on straightforward scenarios, such as unmet safety conditions or basic electrical/pneumatic issues. Intermediate exercises introduce more complexity, covering a wider range of situations.

Advanced exercises challenge students with combined faults, intermittent issues, or controller-related problems.

Stay tuned, as we will periodically introduce new fault scenarios to enhance the application and keep the learning experience dynamic.

WIDE VARIETY OF FAULTS

Students will face a wide variety of faults designed to represent real life situations. In some cases, the operator will prompt some hints on how the machine behaves at the moment to help student identify and isolate probable causes. DiagnozVr covers mechanical, electrical (AC, DC, Continuity), pneumatic and controller faults.

![]()

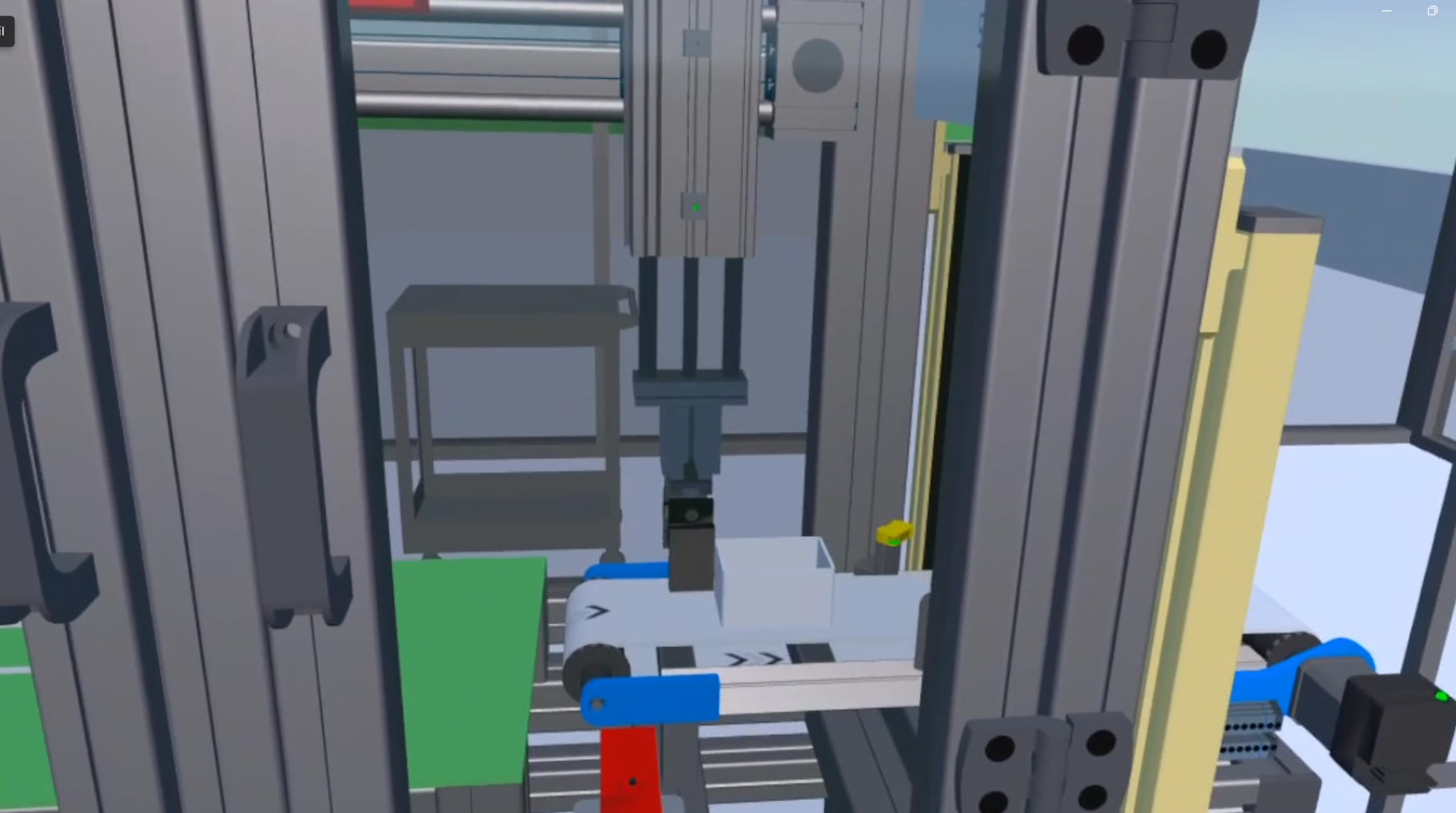

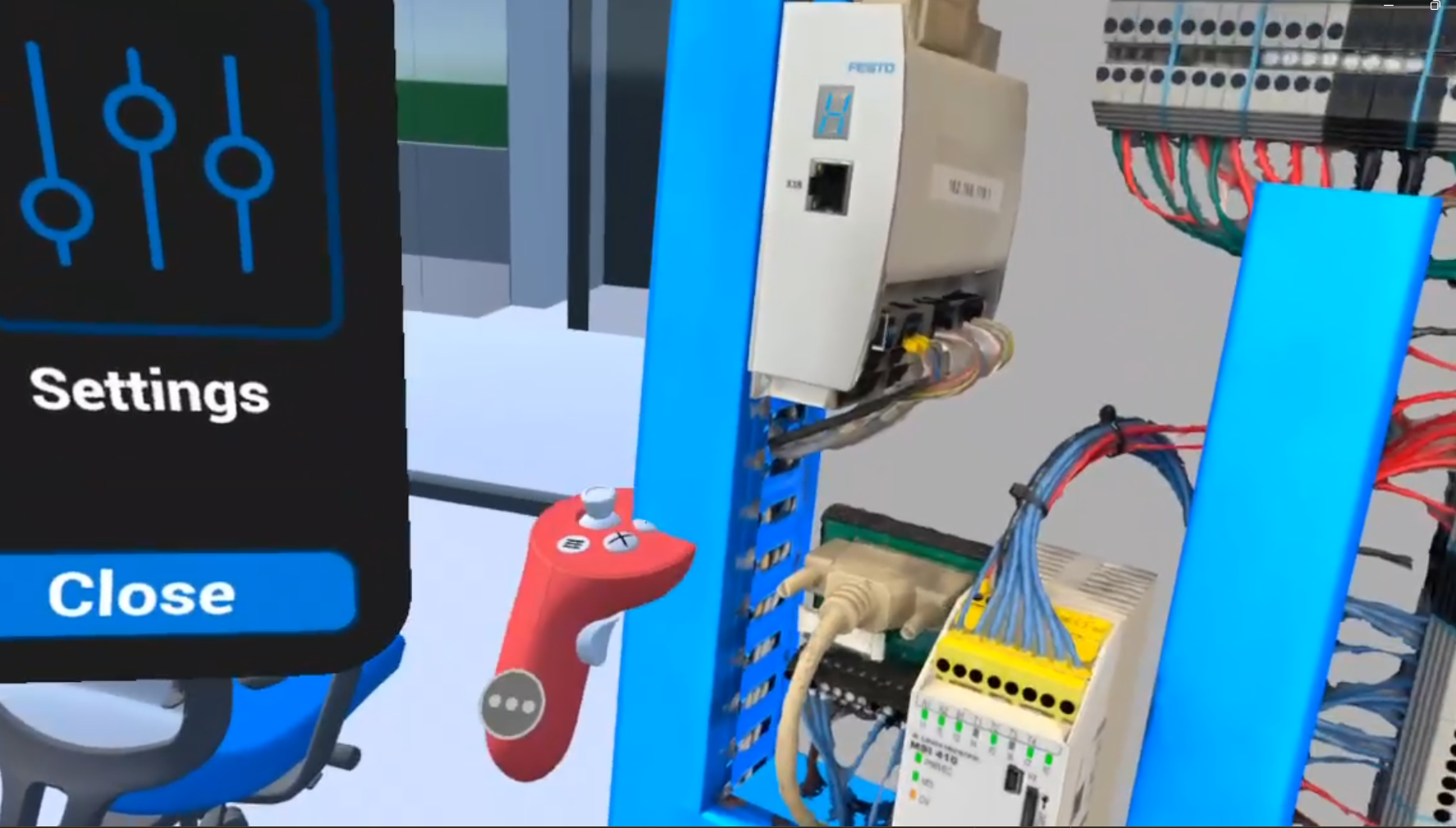

ADVANCED CONTROLLER FAULTS

All controllers, including PLC, Safety, Motion, and Light Curtain, function just like their physical counterparts, enabling students to enhance their understanding of these devices. Students can take measurements directly on the units, fostering hands-on learning. In certain scenarios, they will need to consult the troubleshooting section of the unit to accurately isolate faults code and identify probable causes.

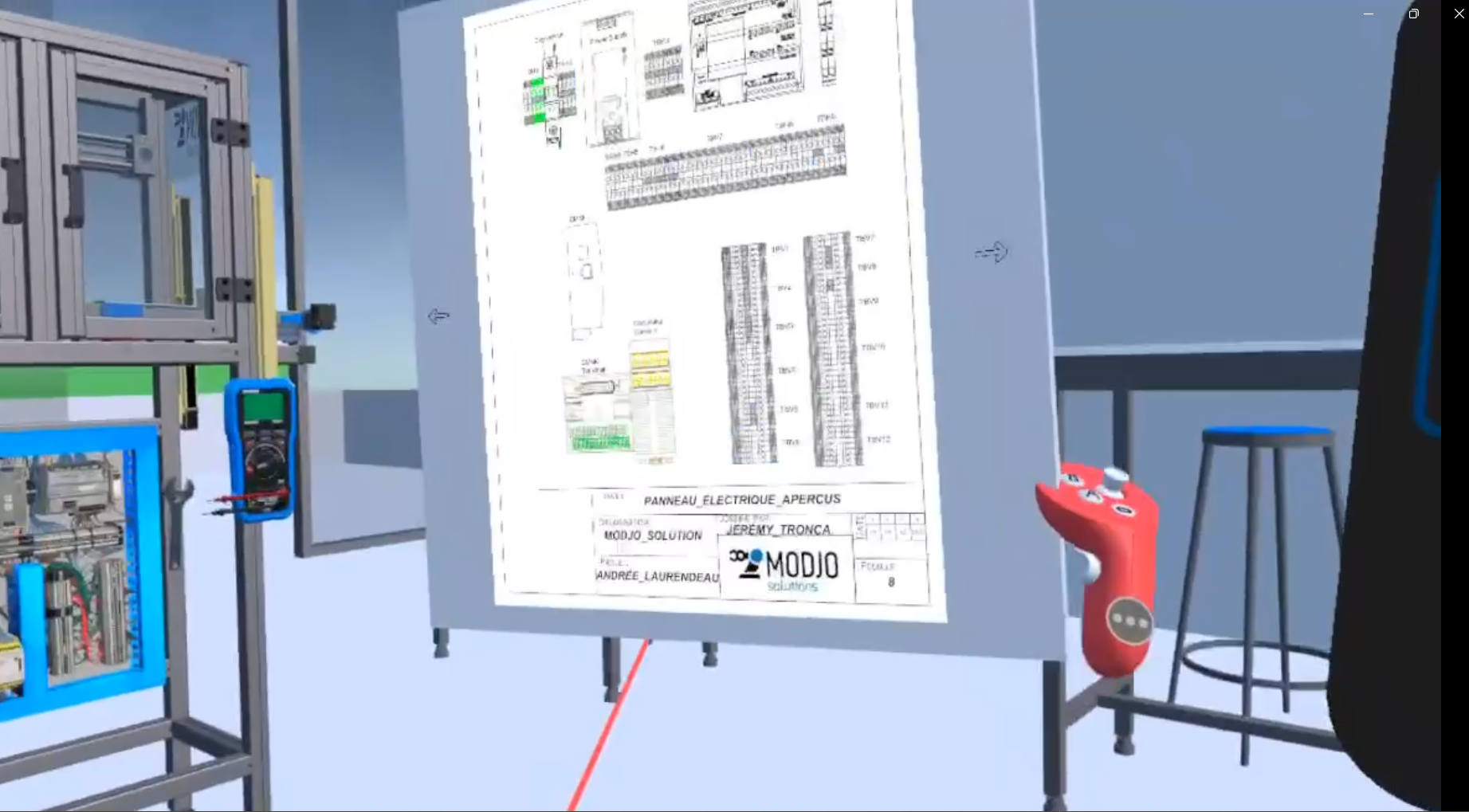

Full documentation

We provide a comprehensive set of documentation, including electrical schematics and general layouts, I/O diagrams, Grafcet sequences, pneumatic circuits, machine safety documentation, and controller error codes.

Students can ergonomically open and position any reference page around the machine, giving them immediate access to the information they need throughout the troubleshooting process.

The simulator is designed for fully autonomous use.

From the moment the application starts, users are guided by an interactive tutorial that explains how to navigate and interact within the environment. Once they feel comfortable, they are teleported in front of the machine, where they can begin a comprehensive series of tutorials.

Users then learn how to operate the machine, use the multimeter, and interact with the control panel. Additional tutorials guide them through launching exercises, using the interactive board, and working with the repair tools available to them.

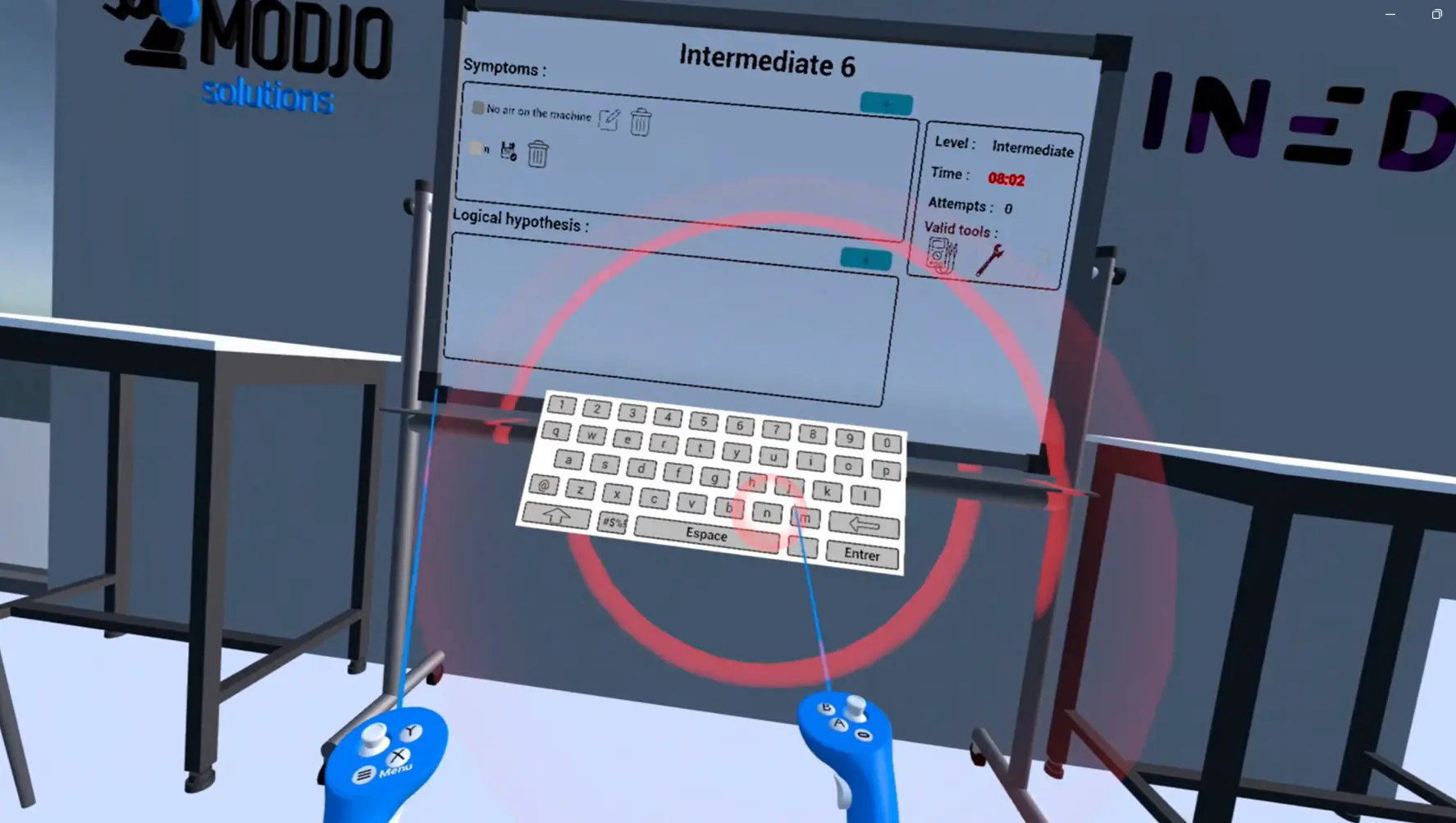

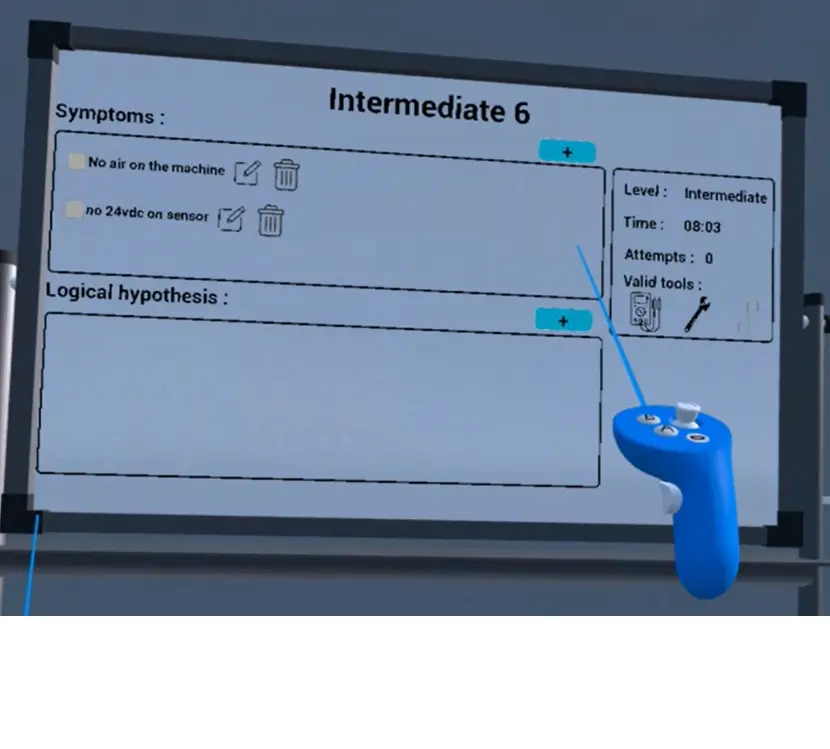

Interactive board

Students are required to complete the interactive board to document their troubleshooting process. This includes describing the observed symptoms and outlining their logical hypotheses regarding the machine malfunction.

The board also tracks several key performance indicators (KPIs), such as time spent on the exercise, the number of repair attempts, and the tools used during the activity. Students receive clear confirmation on the board once the machine issue has been successfully resolved.

BENEFITS FOR TEACHERS

Creating faults on a physical machine in your lab can be a complex and time-consuming process. It often involves manually inducing faults by replacing functional components with faulty ones, a task that must be completed before your lab session and potentially on multiple machines. In most cases, you rely on a fault insertion box, which is limited to a narrow range of electrical faults.

DiagnozVR eliminates all these challenges. No more manual setups or time-intensive preparations. Simply use your cheat code to select the types of faults you want your students to investigate, and voilà! Let them take charge of the troubleshooting process. You can even utilize VR casting options to deliver lectures, set expectations, or present DiagnozVR to your entire class in an engaging and interactive way.

CASTING

Depending on your network setup, there are multiple ways to remotely view the DiagnozVR application and support your students. You can use a phone, tablet, or PC to monitor their progress. Additionally, ArborXR provides a convenient casting option that works seamlessly over your network.

Utilizing the casting feature allows you to closely assist students who may be struggling with fault evaluation or navigating the application. This real-time monitoring ensures you can guide them effectively, provide immediate feedback, and foster a more interactive and supportive learning experience. It’s an excellent way to stay engaged with students while addressing individual challenges directly.

REPAIR MODE AND EVALUATION

When students identify and isolate the probable cause of a failure, they will need to use the virtual key beneath the machine to initiate repairs. They will be required to point and click on the faulty component and select the appropriate action to resolve the issue. In some cases, they may also need to identify the electrical connection between two points to replace a wire.

At the start of an exercise, their performance will be tracked, including the time taken and the number of actions performed to diagnose and repair the faults. This not only prevents cheating but also provides teachers with valuable insights to assess the effectiveness of the students' troubleshooting skills.